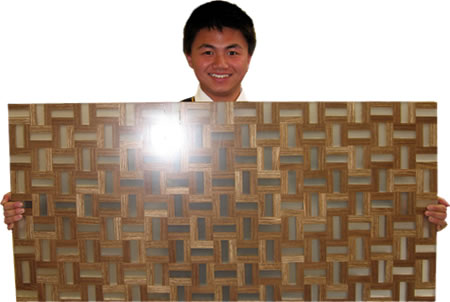

Wood/acrylic laminated coffee table

Tian Liu

Tian Liu

Year 13 Materials Technology

Wellington College

Teacher: Matthew Lane

For his major Year 12 project, Tian had been working with a local cafe on merchandise to help promote the company. This, although successful, hadn't led to any major prospects. Tian had to first find a client, then a project. Potential clients were friends, a local business and family as and after surveying their needs, he chose his mother, May, and then to make a table for her.

Tian's technological practice was exemplary. He thoroughly investigated existing artefacts and materials, paying close attention to the needs, likes and dislikes of his client and extended relations. They decided on a wooden table with an inset acrylic panel and a large slide-out drawer/compartment inset into its complete inner profile, however the specifications were fluid because the client was open to alternative solutions. Tian explored several models – computer-generated as well as physical. Construction techniques were highlighted and analysed – some of them were found wanting, so he developed and modified those.

Through this process of experimentation and exploration Tian came up with a completely new idea for the table top – an interplay of acrylic and wooden blocks. Tian felt he had to change his final design to express this new idea. "If I put this pattern on top of my original design there would be too much happening, which would take the focus from what was now the main feature of this table: the table top." So he came up with a radical new design for the legs, one of which replicated the patterning of the table top's mosaic.

After discussing his rationale for change and the new designs with his client and receiving her approval, Tian set to work on his final outcome. A great deal of experimentation was required to come up with the right techniques to successfully cut, assemble and glue the pieces for the top. Tian then tried machine sanding the finished top, but realised it could only be done using industrial machinery. Matthew Lane contacted Touchwood, a Tawa-based furniture-making company that had hosted student visits in the past, and they agreed to level the top.

The use of a metal base required research and learning how to weld, and experimentation with spraying techniques to get the right finish.

Tian's documentation throughout the project was excellent. He finished his portfolio off with an analysis of how the table could be mass-produced, in which he included aspects of production he had witnessed at Touchwood such as quality assurance and pre-assembly techniques.

Tian's mother was thrilled with the final result. "This is beautiful. I love the new look and the combination of materials," she said. "It will be a highlight in my lounge."

Teacher comment

Tian's table is so unusual. The patchwork quilt idea of the alternating squares of the top is repeated in the frame – the two complement each other superbly. What particularly impressed me was the way he developed his original idea into this solution – the thinking that has gone on throughout was very detailed and analytical, with excellent experimentation. The finished product is outstanding in terms of its craftsmanship and unusual appeal. All the staff and students commented that it was the best piece of work produced at the College in 2007.

Tian's Year 12 Workbook and the modelling used in his subsequent Year 13 project are featured in the case study CP819 A Focus on Modelling.

Tian holding up his coffee table